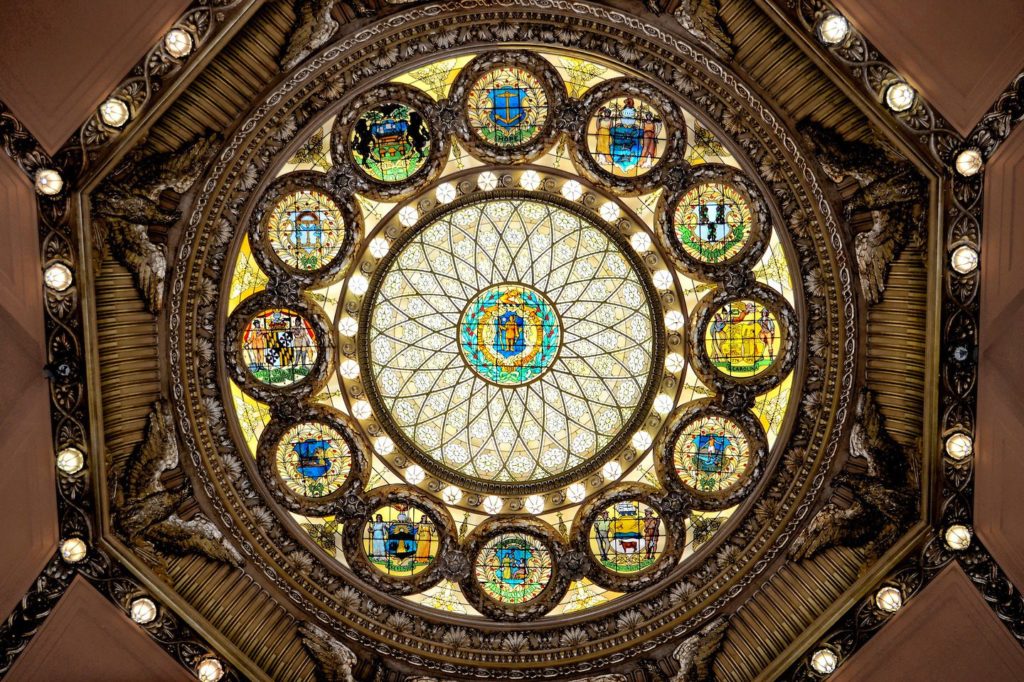

Twenty-one skylights had to be replaced less than 15 years after the original installation because of continuous leaks, which also damaged custom plasterwork. The centerpiece of this project was an expansive atrium skylight over the Great Hall which contained photovoltaic film laminated within the glass, allowing some light transmittance in this very public area.

Challenge:

A very historical building and incredibly busy work site with a steady flow of senators, congressmen, as well as public tours, so minimal impact was crucial.

- Because of past problems, a stringent quality control program was instituted.

- There was a lot of welded copper flashing and gutters and each section had to be submitted for approval before installation.

- All roofing abutting the skylights had to be replaced.

- Creating a green, energy-efficient daylighting solution.

- Finding one company that could supply the two different types of photovoltaics and meet all stringent specifications laid out in the plans.

- Complicated manufacturing process to integrate the thin photovoltaic film within a sealed insulated glass structure not normally meant to house wires and connectors.

Solution:

Wasco’s Pinnacle skylight system was chosen because its leak-resistant sill enclosure guards against air infiltration and water intrusion and it’s perfect for large spans.

- Wasco created a scale model – large enough to walk under – to test the performance of all critical sections, then invited the Massachusetts State House construction management team to the Maine manufacturing facility for review.

- Besides being aesthetically pleasing, integrating the photovoltaic glass into the skylight structure meant that the panels would not have to be removed in any future roof repairs.

- Wasco made deeper, custom pressure bars for the wire and connectors to run under the face caps so as not to compromise the integrity of the system.

- More traditional, non-light transmitting photovoltaic glass units were used in non-public areas.

- The remaining skylights were more traditional non-photovoltaic daylighting systems, and a handful were just re-glazed keeping the existing rafters and purlins while adding new pressure plates and covers.